Electrical Impedance Spectroscopy with a Potentiostat

Electrochemical impedance spectroscopy (EIS) is a powerful technique that utilizes a small amplitude, alternating current (AC) signal to study the

Anycubic Photon S

The Photon S is a DLP (Digital Light Projector) 3D printer, a technology similar to SLA (Stereolithography) but cheaper. It

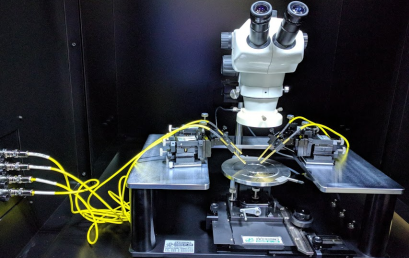

Everbeing C-6 Micro Probe Station

Electrical characterization is a significant part of microelectronic devices. The input and output contacts of a device under test (DUT)

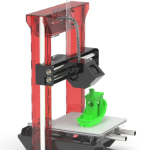

High voltage signal generator

Function generators are a common instrument used for lab bench testing. Usually, for some lab testing, these are commonly available

High temperature probe station for dielectric, impedance, and Ferroelectrics measurements

A probe station is an essential piece of equipment used in condensed matter physics for studying the electrical properties of

the electrical properties of

PhysLogger

PhysLogger is an adaptable tool that enables oneself to measure, analyze, and control physical quantities with live plots and interactive

Plasma Etcher

The plasma etching is a dry etching process whereby the surface material is removed by plasma processes at low pressure.

Imaging Spectrometer

The Horiba iHR550 is a spectrometer capable of being used as both a monochromator and a spectr ograph, i.e.

ograph, i.e.